Introduction to Completion Management Systems

The Process Industry: A Domain of Complexity and Precision

The commissioning phase of a project is often highly complex and requires a significant amount of planning and control to ensure the safe start-up of process facilities. The commissioning team, central to ensuring the seamless integration and optimal functioning of the facility, spends considerable time planning the commissioning activities and populating the completion management system.

Completion Management Systems: Revolutionizing Commissioning

Enter the realm of completion management systems – a crucial system used by the commissioning team and managed by a CMS Administrator. This sophisticated software is not merely a tool; they are comprehensive solution designed to navigate and track the overall commissioning processes. Completion management systems stand out as beacons of efficiency and accuracy in an environment where every minute counts and every detail matters. They streamline workflows, ensure rigorous adherence to safety standards, and maintain the delicate balance between time, cost, and quality – a triad that governs the success of any project.

Understanding Completion Management Systems

Defining the Technological Backbone of Modern Commissioning

At its core, a completion management system is an advanced software solution, designed to manage and track the various activities and phases of a commissioning project. It’s a far cry from traditional project management tools, offering a more specialized approach tailored to the unique needs of the commissioning team. These systems provide a centralized platform where every element of a project – from equipment installation to safety checks – is logged, monitored, and controlled.

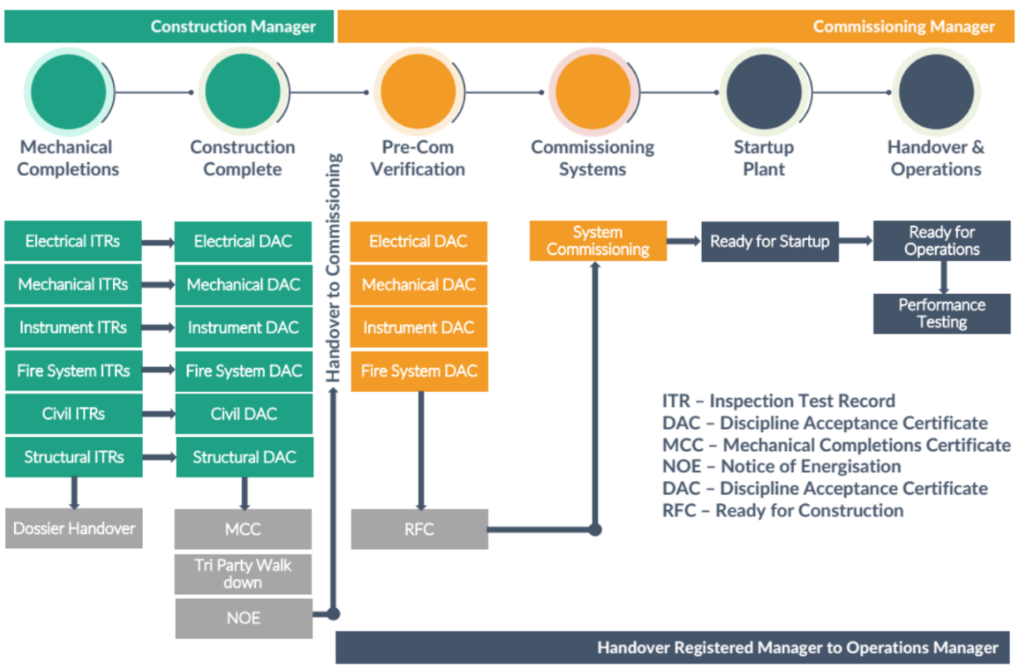

Details recorded in the CMS include the systemization of the entire facility in logical workgroups, inspection test records allocated to each equipment type as well as phase gate certifications that control the energization and handover of each system.

Refer to our article on Why systemisation matters

Benefits for the Commissioning Team

Completion Management System – Streamlining Workflow and Documentation

One of the primary advantages of completion management systems lies in their ability to streamline and systemize complex workflows. For commissioning engineers, who often juggle multiple tasks and oversee numerous systems, these tools are crucial in maintaining engineering integrity and overall completion.

They automate routine tasks, reduce paperwork, and ensure that all project commissioning documentation is centralized and easily accessible. Typical documentation stored with the CMS will include:

- Systemised Piping and Instrumentation Diagrams (P&IDs)

- Systemised Single Line Diagrams and Electrical Schematics

- Inspection Test Records including sign-off and the ITR matrix

- Punchlist (Based on systems)

- Completed Commissioning Procedures

- Handover Certification (MC, RFU, RFSU, Final Handover)

Improving Project Tracking and Accountability

Completion Management systems also enhance project tracking and accountability. With features like real-time progress updates and detailed reporting, commissioning engineers can closely monitor every aspect of the commissioning process. This allows the team to optimize the schedule based on available work fronts as well as flagging systems that are likely to fall behind and require escalation. This visibility not only aids in proactive problem-solving but also fosters a culture of accountability, where each team member is aware of their responsibilities and deadlines.

Key Components of a Completion Management System

Database Management and Data Integration

At the heart of any completion management system is its robust database management capability. These systems are designed to handle vast amounts of data, from equipment specifications to safety protocols. Furthermore, they integrate seamlessly with existing databases and engineering software, ensuring that all data is consistent, up-to-date, accessible, and backed up.

Real-Time Monitoring and Reporting Capabilities

Real-time monitoring is another crucial feature. These systems provide commissioning engineers with live updates on various aspects of the project, enabling them to make informed decisions swiftly. Coupled with comprehensive reporting tools, they can track progress, identify bottlenecks, and address issues before they escalate. This information is often reported through to the overall project and operations management as it directly influences the production start dates.

Compliance and Safety Management Features

Safety and compliance are paramount in the process industry. Completion management systems are equipped with features that help maintain high safety standards and ensure compliance with industry regulations and project requirements. This includes tracking safety inspections, recording compliance checks, and ensuring that all procedures adhere to the required standards. Most importantly, the CMS system provides a formal phase gate system, ensuring system energization and commissioning activities do not take place until safe to do so. The CMS system will also provide the requirements for handover completion and ensure that any punch list items are closed before handover.

Challenges and Solutions

Navigating Implementation Hurdles

Implementing a new completion management system can be challenging for those who lack the correct experience. Incorrectly planning or implementing the CMS has the potential to facilitate unwanted safety events, as well as unnecessarily increase the commissioning efforts and overall costs. Failure to correctly systemize the facility as well as incorrectly linking handover dependency could result in the energization of systems before all equipment is ready to do so. Whereas over-complicating the completion build can hinder the commissioning team’s progress and create unnecessary delays and re-testing. For this reason, an experienced Commissioning Manager and Commissioning Team must work closely during the CMS build stage.

Ensuring User Adoption and System Flexibility

Another key to success is ensuring user adoption. This involves tailoring the system to meet the specific needs of the project and its team (this is relevant to both the Construction and Commissioning Teams). Flexibility and customization are essential, as they allow the system to evolve in tandem with project requirements. Regular feedback loops with users can also provide valuable insights for continuous improvement. The Completion Management System should be viewed as a live system, with systems and ITRs often modified as the commissioning phase executes. Although the CMS build is subject to change during the commissioning process, it is critical to ensure correct change management and approval of any changes to avoid unwanted impacts on safety, plant, or schedule.

Future Trends and Developments

Embracing Emerging Technologies

The future of completion management systems in the process industry is intrinsically linked with technological advancements. Emerging trends include paperless sign-off, the integration of artificial intelligence for predictive analytics, the use of augmented reality for training and on-site inspections, and greater connectivity with Internet of Things (IoT) devices. These developments promise to further enhance efficiency, accuracy, and safety in commissioning processes.

The selection of CMS software will be dependent on project requirements and budget, however, some of the products we have used include:

https://www.aletheiacms.com.au/

https://hexagon.com/products/intergraph-smart-completions

Predictions for Industry Impact

As these systems become more advanced, they are expected to play an even more central role in commissioning management. The ability to predict and preemptively address potential issues will significantly reduce downtime and costs. Moreover, the increased emphasis on data-driven decision-making will foster a more agile and responsive approach to the commissioning effort.

Need Help?

The commissioning experts at Nextek have over 30 years of Commissioning experience, including the selection and build of Completion Management Systems for the Mining, Process, and Chemicals industry.

Contact us today!